- Published on

- Authors

- Name

- Plant Health

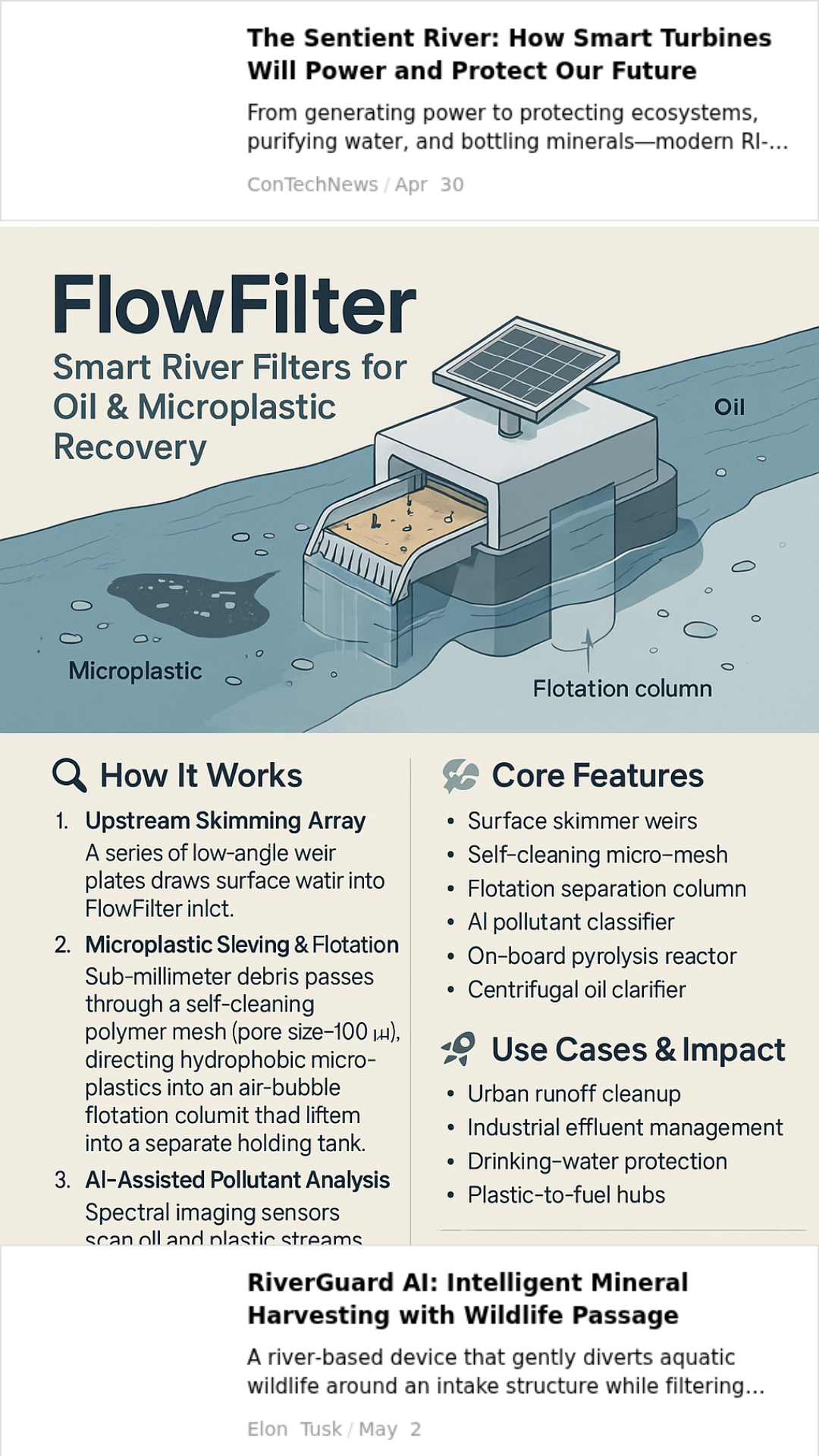

Rivers are the lifeblood of ecosystems—but they also carry persistent pollutants: free‑floating oils from runoff and tiny plastic particles that evade conventional screens. FlowFilter is a modular in‑stream device that skims, separates, and repurposes these contaminants, converting them into reusable oil and feedstock for circular‑economy plastics.

🔍 How It Works

Upstream Skimming Array

- A series of low‑angle weir plates draws surface water into the FlowFilter inlet.

- Buoyant oil droplets accumulate on the weir and are channeled into a floating collection tray.

Microplastic Sieving & Flotation

- Sub‑millimeter debris passes through a self‑cleaning polymer mesh (pore size ≈100 µm).

- Hydrophobic microplastics are directed into an air‑bubble flotation column that lifts them into a separate holding tank.

AI‑Assisted Pollutant Analysis

- Spectral imaging sensors scan oil and plastic streams in real time, classifying types (engine oil, cooking grease, polyethylene, polypropylene, etc.).

- A machine‑learning model adjusts flow splits and purge cycles to optimize capture rates for varying pollutant loads.

On‑Board Recycling Modules

- Thermal depolymerizer converts microplastic concentrates into pyrolysis oil.

- Centrifugal oil clarifier removes water and particulates from reclaimed oils, readying them for resale or local use.

Telemetry & Maintenance

- Solar‑powered controls report pollutant volumes, conversion yields, and device health to a cloud dashboard.

- Automated back‑flush cycles clear debris; alerts notify operators when tanks approach capacity.

🔧 Core Features

| Feature | Description |

|---|---|

| Surface Skimmer Weirs | Passive oil‑skimming plates that direct floating oils into a containment tray |

| Self‑Cleaning Micro‑Mesh | Automated polymer filter that captures sub‑millimeter particles and periodically sheds accumulated debris |

| Flotation Separation Column | Air‑bubble lift for sorting hydrophobic microplastics from water |

| AI Pollutant Classifier | Hyperspectral sensors and ML that distinguish oil grades and plastic types, optimizing processing routines |

| On‑Board Pyrolysis Reactor | Low‑temperature thermal depolymerization of plastics into synthetic oil |

| Centrifugal Oil Clarifier | High‑G centrifuge that purifies reclaimed oils, removing water and fine particulates |

| Remote Monitoring Suite | Cloud dashboard with live pollutant metrics, yield analytics, and automated maintenance scheduling |

🚀 Use Cases & Impact

- Urban Runoff Cleanup: Deployed at storm‑drain outfalls to intercept oils from roads and microplastics from tire wear before they reach larger waterways.

- Industrial Effluent Management: Installed downstream of food‑processing plants or vehicle‑wash facilities to harvest cooking grease or machine oils for reuse.

- Drinking‑Water Protection: Pre‑treats river intakes for municipal water plants, reducing load on downstream treatment and lowering costs.

- Plastic‑to‑Fuel Hubs: Community centers collect filtered plastics and convert them on‑site into pyrolysis oil, creating local revenue streams.

- Environmental Research Stations: Continuous sampling of microplastic flux helps scientists map pollution hotspots and evaluate policy interventions.

⚖️ Ethical & Environmental Considerations

- Fauna Safety: Intake velocities and mesh spacing are certified to prevent entrainment or entanglement of fish, amphibians, and macroinvertebrates.

- Energy Efficiency: Entire system runs on solar power with ultra‑low‑power control chips; back‑flush cycles are minimized to conserve energy.

- Residue Management: Spent filter solids and reactor byproducts are contained in removable cartridges for certified downstream recycling or safe disposal.

- Data Sovereignty: Local communities retain full ownership of monitoring data, with optional anonymized sharing for environmental agencies and researchers.

💡 From the Founder: Turning Pollution into Potential

“Oil slicks and microplastic clouds aren’t just environmental crises—they’re untapped resource streams.

FlowFilter treats rivers as recycling conveyors, not mere conduits.

By capturing and converting these pollutants on‑site, we close the loop on riverine waste, empower communities, and protect wildlife—all in one elegant module.”— Eric D., Quantum Creative Solutions

🌟 Envisioning a Network of Clean Waters

Picture thousands of FlowFilter units hugging waterways around the globe—urban creeks, industrial canals, agricultural drains—all working in concert to harvest unwanted oils and reclaim plastics before they fragment further. Together, they form a riverine recycling grid, turning pollution into prosperity and ensuring every drop flows cleaner and smarter.

Welcome to the filtered future—where rivers not only nourish life, but also fuel a circular economy.